Understanding Sublimation: Significance of Sublimation Transfer Printing

The Wonders of Sublimation Printing

Ready to get your creative juices flowing? Here's a lowdown on sublimation printing, the incredible technique that can transform your designs onto a variety of materials.

What is Sublimation Printing? Imagine a magical process that transfers your desired design from a solid state into a gas, only to transform back into a solid on the fabric. That's sublimation printing for you! Unlike traditional printing, where the design sits on top of the material, sublimation prints are embedded within the fabric fibers, resulting in designs that are less prone to cracking, fading, or peeling.

The Sublimation DanceFirst, your design is printed onto a special transfer paper using a digital printer and sublimation ink. Once the transfer is complete, a heat press is employed to heat the design, causing the inks to become gases that penetrate the pores of the polyester fabric, leaving a permanent, full-color image. Throughout this process, the heat opens the fabric's pores and permits the gaseous inks to sink in. When the heat press cools down, the pores close, trapping the inks inside the material.

Printers for Sublime CreationsTo ensure that you're harboring the right tools for the job, you need a printer that can handle sublimation ink effectively. Sublimation printers commonly use water-insoluble dispersion dyes, otherwise known as "sublime" or specialized sublimation printers. Unlike regular inkjet printers, these printers require special handling due to the ink's consistency and temperature sensitivity.

Benefits of Sublimation PrintingSublimation printing has taken the artistic world by storm, with its many advantages:

- Versatility: Sublimation allows you to print intricate, photo-like designs on a wide variety of materials with ease and relatively low cost.

- High Precision: The high resolution of sublimation printing ensures that your designs retain their vibrant colors and detailed elements, without the need for post-treatments or extended wait times after the transfer.

- Long-Lasting Colors: Since the ink is embedded within the fabric, the colors are not easily fragile or prone to fading. Moreover, sublimation printed garments are resistant to environmental factors such as UV rays, making them suitable for outdoor applications such as flags and banners.

- Durability: The ink does not seal the fabric, preserving attributes such as breathability that make it ideal for sportswear and club jerseys. Plus, sublimation printing is eco-friendly, since no binding agents or solvents are required during the process.

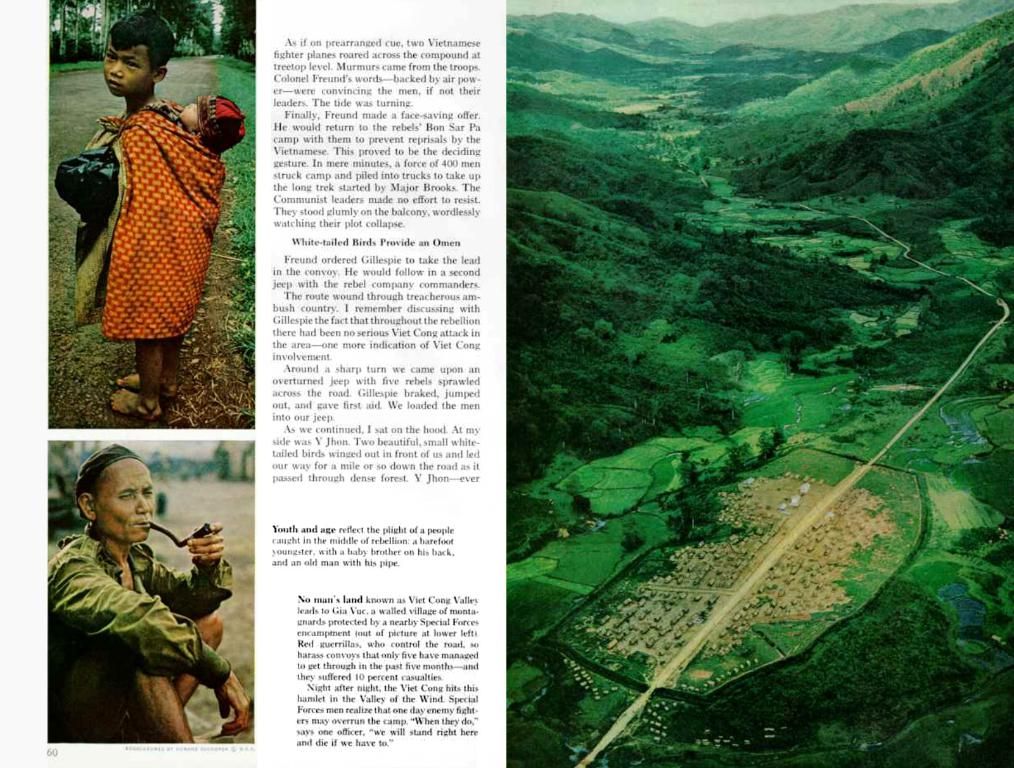

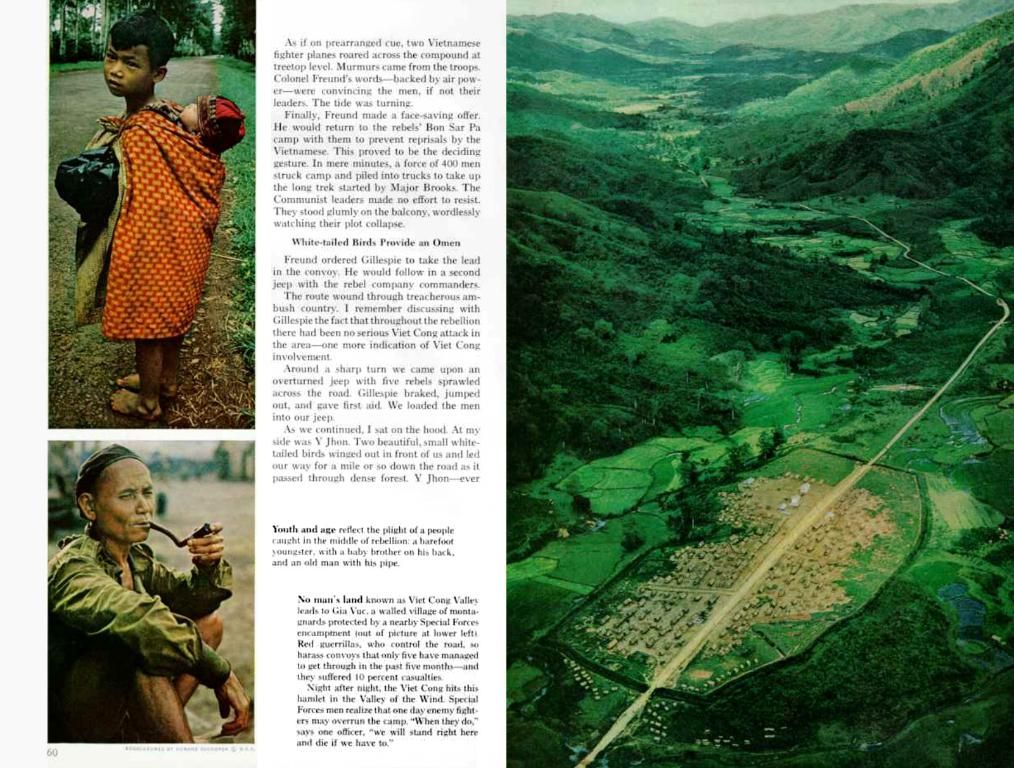

The Sublime Connection: From Skin to ClothingSublimation is like getting a tattoo, but for your clothing! The process involves heating the fabric to fuse the ink with it, essentially transferring your design permanently. The end result is a permanent, full-color image that won't peel, crack, or wash off the material.

Choosing Sublimation Over Other TechniquesWhen compared to other printing methods like screen printing, transfer vinyl, and direct-to-garment printing, sublimation stands out for its high-quality, vibrant colors, and durable, permanently transferred images. Plus, the low material cost and minimal setup requirements make it an affordable choice for small and large-scale projects alike.

Sublime ExamplesSublimation is a process by which a solid turns into a gas without becoming a liquid. Common examples include ammonium chloride, solid iodine, and dry ice. Dry ice, or frozen carbon dioxide, is the ultimate example of sublimation. When exposed to air, it transforms directly from its solid state to a gaseous state, causing visible fogging.

So, go ahead and unleash your creativity with sublimation printing – the world is your sublimation canvas!

Enrichment insights:

- You can achieve the best results with dedicated sublimation printers like the Sawgrass Virtuoso SG500 and SG1000, known for their ease of use, high-quality prints, and automatic maintenance features. Other suitable options include the Epson SureColor F570 Pro for large-format sublimation and some Epson models that can be converted for sublimation by replacing the ink. For large-scale production, industrial models like MTuTech sublimation printers are recommended.* Key features of a suitable printerfor sublimation printing are specialized ink compatibility, material compatibility (polyester, ceramics, and metal), print resolution and speed, and maintenance and reliability.

- For those interested in expanding their creative horizons, sublimation printing can be considered as an alternative to screen printing, especially when wanting to achieve vibrant, long-lasting, and intricate designs on a variety of gadgets and materials, including T-shirts, mugs, or phone cases, using the latest technology.

- When venturing into the realm of sublimation printing, it's essential to invest in a technology that can effectively handle sublimation ink – consider a specialized printer, such as the Sawgrass Virtuoso or an Epson model converted for sublimation, which cater to producing high-quality, visually striking prints on polyester, ceramics, and even certain types of metal, a significant upgrade from ordinary gadget printers.