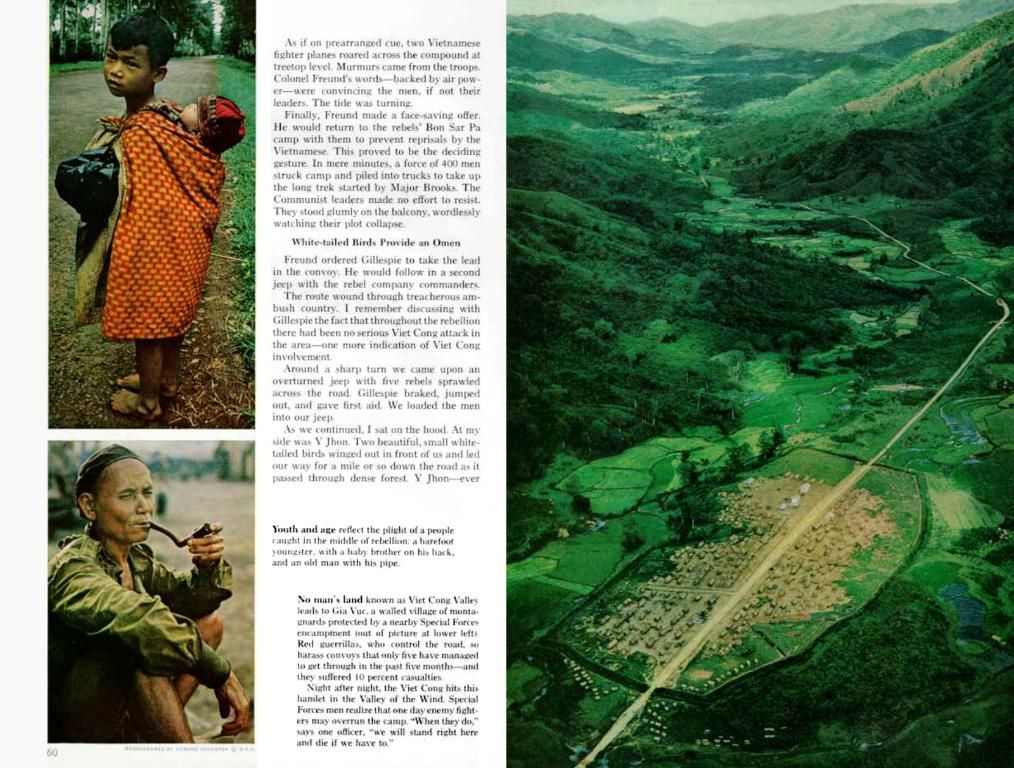

Printers intrude on construction site

Revamped and Modernized Construction through 3D Printing

A decade ago, 3D printing in construction was hyped as the revolutionary technology of the future, promising to reshape the construction industry. Yet, the revolution failed to materialize, and today it's evident that the sector remains one of the most conservative in the economy. However, 3D printing in construction has survived and evolved, demonstrating its utility in various applications.

In the past decade, construction printers have transformed from an extravagant concept into a viable technology. Last year, 80 buildings, including residential, commercial, and public buildings, were 3D printed in Russia. Mass production of construction printers is now a reality, and the technology is advancing globally. For instance, in the United States, a community of 100 3D-printed homes was recently completed[1]. 3D printing has proven its potential and is now being integrated into the construction technology spectrum, with a chance to become a successful niche product.

Robotics in Construction

In the mid-1990s, Professor Behrokh Khoshnevis from the University of Southern California proposed the revolutionary idea of creating a massive printer capable of printing entire buildings. In 2009, the Contour Crafting giant 3D printer, developed by Khoshnevis on a grant from the University of Singularity, marked a significant step in the construction field. Initially, it was envisioned that such a device would be used on the Moon and Mars. Under the guidance of American professor Khoshnevis, numerous experiments with construction materials were conducted. However, the boom began much later - in 2014.

"In 2014, the patent for Khoshnevis' invention expired, and numerous companies began manufacturing printers and constructing buildings. A hype ensued, making the topic very trendy. For example, numerous Chinese companies emerged, but they significantly simplified the idea," says Andrej Rudenko, head of the American company Total Kustom. Rudenko, a Russian engineer in the US, is a pioneer in this new field: in 2014, he built a printer, printed detailed elements of a Gothic-style gazebo covering 3-5 square meters, and assembled the structure on his own land. The following year, Rudenko built a 22 square meter apartment as part of a hotel in the Philippines. These projects demonstrated that 3D-printed homes can be of high quality[1].

So, what exactly is a construction printer, and what is it like to print on it? Romantic imagery portrays a device akin to a robotic vacuum cleaner that magically prints houses on-site. When the author first saw the printing process a couple of years ago, he was disappointed by the gap between the promised revolution and reality. Firstly, there were several workers constantly occupied. Secondly, a regular concrete mixer was in constant use, which was far from the impression of a futuristic technology. Lastly, the printer appeared too industrial and not fashionable. This device was a portal-type structure: a large metallic frame with three arches, on which a moving crane supported the printing head, into which a special concrete mix was fed. However, modern-day printers, such as those from RVS, are much more photo-friendly.

But the printing process was indeed captivating. The extruder nozzle, fed with concrete, moved on a mobile cart. The head moved quickly and along a complex trajectory, laying down one layer of several centimeters thick on the already set layer below.

Research is ongoing for the ideal construction material. Companies are experimenting with different approaches. Some are trying to apply foam polymer-based concrete, which would make the printed walls insulated[1]. However, the most popular approach currently is printing using a quick-setting cement - a common method in modern 3D construction.

Efforts are also being made to use polymers as a construction material. For instance, the D-Shape printer company operates using an exotic technology: it prints by layering a powdered material, which is then saturated with a binding solution. Furthermore, two additional types of printers have emerged: portable printers, set up directly on the construction site, and factory-based printers, where pre-made parts are assembled[1].

Why Choose 3D Printing of Buildings?

The image of a revolutionary technology has largely been justified: 3D printing has successfully attempted to robotize the traditionally anti-innovative construction sector. Interest in this method is driven by several potential benefits.

Firstly, robotization allows for a significant reduction in the number of workers on construction sites: only three or sometimes two people are required for a single-story building's construction, resulting in labor cost savings—a factor that contributes to the technology's active development, especially in the Middle East. In fact, the United Arab Emirates even has a state program: by 2030, 25% of new cottage settlements are expected to be built with 3D printing[1]. In a labor-shortage context, this factor is crucial, and it also applies to Russia.

Secondly, ecofriendliness. In its potential, 3D printing offers clean, quiet, intelligent construction. With water and electricity on site, only the printer and the necessary concrete mix are brought in. There are no waste products, significantly reducing logistics costs[1].

Thirdly, speed. "A 100 square meter building can be constructed in 100 hours by a team of three," notes Michael Shilenkov, general director of SmartBuildService. However, Roman Pavlenko, general director of 3d4art, advises a more realistic perspective: "There are many claims such as "a house was printed in 20 hours" or "in 50 hours", but these calculations do not include the printer's downtime and the time required to prepare the site and printer." Pavlenko, an experienced 3D builder, was the one who printed one of the world's largest buildings in 2021—a community center in Tatarstan.

It has been proven that the printing of walls can be very fast. However, this potential can only be realized with the combination of several factors. For example, the expertise of the construction team, high-quality concrete mixture, and favorable weather conditions play crucial roles[1]. Moreover, printing can only be done for the external walls and occasionally the roof. However, other work, such as plumbing and electrical wiring, must still be done, and the walls must be rendered if they have a rough texture[1].

Lastly, in Russia, there is considerable potential for 3D printing to become a global leader in a specific niche of high-technology construction. "In the US, the criteria for a building made by a new technology are simply: it must be as affordable as a prefabricated house," explains Andrej Rudenko. However, the cost of construction often varies inversely with its size. Nevertheless, in the next couple of years, the economic viability of 3D construction will be tested not on experimental buildings but on a mass scale[1]. In Russia, plans are underway to build several settlements with 3D-printed homes.

"The market is tarnished by the myth that 3D printing houses are extremely cheap. This is not true. Walls occupy no more than 10-15% of the overall cost. All other expenses—windows, roof, interior works, engineering—are the same as in any other house. Yes, savings can be made by reducing labor costs and construction time, but drastic reductions in costs should not be expected. It's more accurate to say that this technology allows for the construction of houses of any design at a reasonable price. Typical prefabricated houses are cheaper to build," says a builder of 3D houses.

The uniqueness of the architectural design has recently become a significant selling point. Indeed, the method removes traditional constraints and allows for, for example, the construction of biomorphic, nature-inspired homes. While such buildings could also be constructed using traditional methods, 3D printing seems to be a more economically justified and logical choice as we move toward reducing conventional box-like buildings and embracing organic design[1].

Remaining disadvantages of the method include the high cost of 3D printers. In Europe, a printer can cost up to 1-2 million euros. Russian models are much cheaper—around 10 million rubles. Nevertheless, builders and clients must still make a significant investment in the technology[1]. Another disadvantage is sensitivity to external conditions. For instance, printing cannot be done in strong winds or heavy rain[1]. Previously, the rough, ridged texture of the walls was considered a disadvantage and required smoothing with plaster, but in recent years, rough textures have become trendy[1].

Russia Leads in 3D Construction

Surprisingly, Russia has emerged as a leading country in the 3D construction sector. In 2016, a house was 3D-printed in Yaroslavl. Today, there are already over ten companies in the country that manufacture construction printers, with Yaroslavl-based AMT leading the series production: over 400 units have been sold worldwide.

Moreover, the United States and other countries have several notable companies in the sector founded by Russian expatriates—for example, Total Kustom by Andrej Rudenko and Apis Cor by Nikita Chen-you-taya. The startup Mighty Building by Vyacheslav Solonitsyn and Dmitry Starodubtsov recently raised over $50 million in investments to construct a plant for printing wall panels made of polymers[2].

In Russia, buildings with 3D technology are being constructed. In a village in Tatarstan, the company "Tatneft" built an 11-meter high community center, one of Europe's tallest buildings built using 3D printing, and one of the largest buildings worldwide by size, with a floor area exceeding 1600 square meters[3]. It's worth noting that the management of "Tatneft" chose 3D printing not only because it was innovative but also as a means to stimulate the use of innovations in the construction sector[3].

The construction of unique homes has been made possible thanks to 3D printing. In an eco-park owned by Dmitrii Cherepkov, the first house was built according to a design by famous architect Totan Kuzembayev, and several more followed[3]. All houses in the eco-park have a complex architecture: they are curved, boast an unusual silhouette. For tourist properties, 3D printing is an excellent fit: buying a 3D-printed house may be risky, but renting one for several days allows for a new experience. This year, plans are underway to build a spa center covering 2000 square meters in the eco-park.

It seems that Russia has all the necessary conditions for the development of 3D printing in the construction sector: a strong engineering education, interest in low-rise housing, a labor shortage, and enthusiasts in the field. However, the chance to become a global leader in this specific niche of high-tech construction hinges on government policy. In contrast to the United Arab Emirates, in Russia, no measures are being taken to support developers and manufacturers[3].

- With the increasing popularity of 3D printing in construction, there is an opportunity for investors to invest in technological advancements in real-estate development, focusing on companies that specialize in the creation of construction printers and the development of new materials for construction.

- As the construction industry adopts 3D printing technology, there is potential for technology companies to collaborate with construction firms, offering innovative solutions that can enhance the efficiency and speed of 3D printing in the real-estate sector, thus reducing costs and improving the overall construction process.