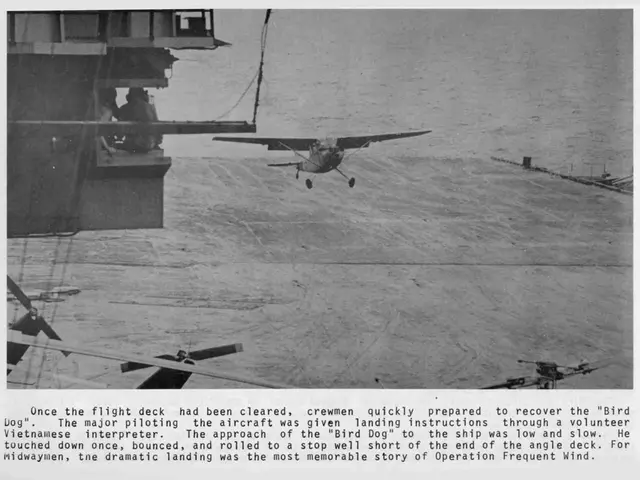

Innovative laser technology introduced for streamlining food and drink packaging by Sidel

Domino Printing Sciences and Sidel Introduce New Technologies for Life Sciences Manufacturers

Domino Printing Sciences and Sidel have recently unveiled new technologies aimed at revolutionising the life sciences industry.

Domino Printing Sciences has introduced the K300 piezo inkjet printer and the Dx-Series range of CO2 laser coders. The K300 printer, designed specifically for the life sciences industry, offers advanced variable data printing capabilities. It is suitable for applications on blister foils, flexible films, medical papers, single-dose blow-fill-seal ampoules, and vials. The new printer can print 2D codes at the individual dose and item level, providing end-to-end solutions for advanced variable data printing.

The Dx-Series range of CO2 laser coders, introduced alongside the K300 printer, offers versatility and precision in coding operations.

On the other hand, Sidel has announced that it will present laser systems at the drinktec 2025 exhibition. These systems, including the EvoBLOW Laser technology, are set to advance the development of lighter PET and rPET bottles in the food and beverage industry. The EvoBLOW Laser technology uses laser-based heating for precise material control, enabling lightweighting even for premium bottles. This technology allows for lightweighting in previously inaccessible areas such as beneath the bottle’s neck.

One of the standout features of the EvoBLOW Laser is its ability to utilise up to 36 heating lines, providing control over the material's thickness along the entire container. This control results in thicker material rings that make the bottle feel and act stronger while using less overall material. The EvoBLOW Laser also eliminates downtime at every stop and start, with no 'stand-by' mode required.

Moreover, the EvoBLOW Laser technology aims to reduce preform waste by 50% compared to traditional solutions. The cold oven technology allows fast access to the oven without waiting for cooling, with zero risk of burns. Live speed modulation in the EvoBLOW Laser improves efficiency by automatically adjusting the blower’s speed in real-time.

Last year, Videojet Technologies unveiled its 7920 UV laser marking system, aiming to boost ease-of-use, flexibility, and reliability in coding operations. The new printer and coders from Domino Printing Sciences do not mention any specific lightweighting or waste reduction capabilities like the EvoBLOW Laser technology. However, each heating line on the EvoBLOW Laser requires only one process setting (intensity), ensuring consistency in thermal profiles.

The laser technology allows for lightweighting in previously inaccessible areas such as beneath the bottle’s neck, a feature not mentioned in the new printers and coders from Domino Printing Sciences. Nonetheless, these new technologies from both Domino Printing Sciences and Sidel are poised to bring significant advancements to the life sciences industry.

Read also:

- Industrial robots in China are being installed at a faster rate than in both the United States and the European Union, as the global market for these robots faces a downturn.

- Hyundai N affirms transition to hybrid performance-centric models, initiating with Tucson N

- EAFO Research Uncovers Crucial Elements in Electric Vehicle Adoption within the EU

- Stock markets in India anticipated a moderate opening, influenced by mixed signals from global markets.